One person, 10 seconds, 10 sealing rings formed! “This is not a scene from a science fiction movie, but a production miracle that actually happens in a modern factory. While traditional manufacturing was still worrying about low labor efficiency and unstable yield rates, the Zoomlea fully automatic Silicone seal ring bonding machine, with its astonishing speed of “10 strips in 10 seconds,” completely overturned industry recognition and made a 500% increase in efficiency no longer a dream!

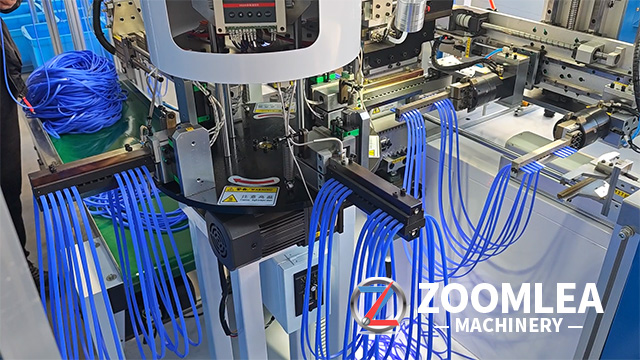

The reason why this device can achieve such astonishing efficiency improvement lies in its unique “multi station synchronous production” technology.

Simultaneous production at multiple workstations, time folding effect

The Zoomlea Silicone seal ring bonding machine decomposes the bonding process into independent steps such as feeding, cutting, bonding, pressing, testing, and unloading through modular design and intelligent system. One machine can simultaneously perform the production task of sealing rings, forming a “time folding” effect. Simply put, this machine is designed with 10 workstations that can simultaneously complete cutting, bonding, and other processes, maximizing production time. This design allows the device to produce 10 sealing rings within 10 seconds, which is tens of times more efficient than manual labor!

Intelligent scheduling, flexible production

In addition to multi station synchronization, the intelligent system of Zoomlea Silicone seal ring bonding machine is also the key to its efficient production. The system can automatically adjust the operating rhythm of each workstation according to production tasks, ensuring that the equipment is always in the optimal load state. Meanwhile, through modular design, the equipment can quickly replace fixtures and programs, and adapt to the production of sealing rings of different specifications and materials.

In the past, we had to shut down and debug for 4 hours to produce sealing rings of different specifications by changing production lines. Now, with Zoomlea’s equipment, it can be done in 10 minutes! “Said the person in charge of a sealing ring production enterprise excitedly.” This flexible production capacity allows us to quickly respond to market demand and seize market opportunities

Quality assurance: no bubbles, no cracks, excellent sealing performance

At the same time as improving efficiency, Zoomlea’s fully automatic Silicone seal ring bonding machine is also on par in terms of quality assurance. The equipment adopts a unique bonding process, which achieves high-quality bonding of the sealing ring in a short period of time through precise control of the heating and cooling processes.

Efficient curing, uniform distribution

The Zoomlea Silicone seal ring bonding machine utilizes an efficient curing system to ensure that the adhesive is evenly distributed and quickly cured in a short period of time. Its advanced temperature control algorithm can automatically adjust temperature parameters according to the characteristics of different materials, avoiding quality problems caused by high or low temperatures.

It’s like performing a ‘precise surgery’ on the sealing ring, with strict control over every step to ensure even distribution of adhesive and sufficient curing, “said a quality management personnel evaluating the curing effect of the Zoomlea Silicone seal ring bonding machine.” The sealing performance and durability of the sealing ring produced in this way have been greatly improved

Defect free bonding, consistent quality

By precisely controlling the heating and cooling processes, the Zoomlea Silicone seal ring bonding machine achieves defect free bonding, ensuring that there are no bubbles or cracks in the bonding area. This breakthrough not only improves the sealing performance of the product, but also extends its service life.

We have conducted comparative tests and found that the sealing rings produced by Zoomlea equipment are significantly better than traditional manually bonded products in terms of pressure resistance, temperature resistance, and corrosion resistance, “said the purchasing manager of an automotive parts company.” This quality assurance gives us full confidence in Zoomlea equipment

Fully automated operation: easily controlled by one person, reducing labor costs

In the current era of increasing labor costs, the fully automatic operation design of Zoomlea’s fully automatic Silicone seal ring bonding machine undoubtedly brings good news to enterprises. From material loading, positioning, heating and bonding, cooling and shaping to finished product unloading, the entire process does not require manual intervention, achieving true “one click” operation.

Previously, we had to allocate several workers on one production line, but now with Zoomlea’s equipment, one person can easily handle it, “said the person in charge of a sealing ring production enterprise.” Just labor costs alone can save hundreds of thousands of dollars a year

In the tide of intelligent manufacturing, the Zoomlea fully automatic Silicone seal ring bonding machine, with its excellent efficiency and quality assurance, not only solves the efficiency and quality problems in traditional production modes, but also promotes the transformation and upgrading of the sealing ring manufacturing industry towards automation and intelligence.

If you are also a practitioner in the sealing ring manufacturing industry or interested in intelligent manufacturing, you may want to pay attention to the Zoomlea fully automatic Silicone seal ring bonding machine. I believe this device will definitely bring you unexpected surprises!

MESSAGE