The practical data of a certain aviation parts enterprise is shocking: tasks that originally required 10 workers and 8 hours to complete can now be completed in 2 hours with only 1 worker operating t...

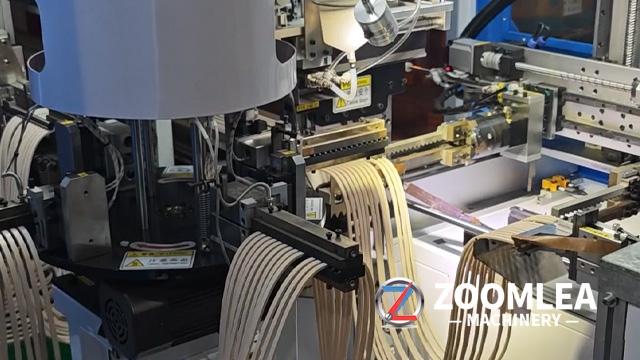

In the field of seal ring manufacturing, material compatibility has always been a key bottleneck that restricts production efficiency and cost. Traditional equipment often can only adapt to a single ...

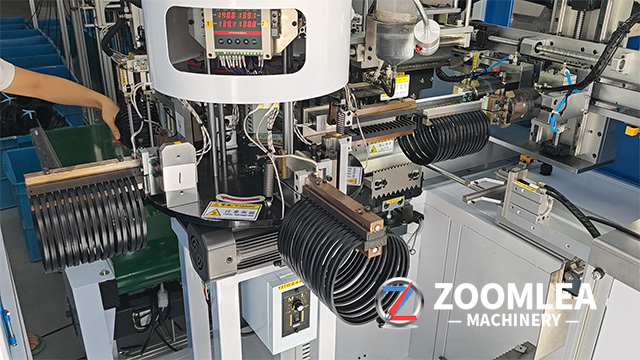

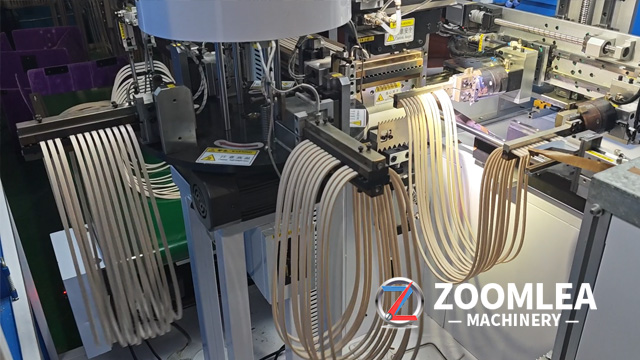

What can be done in 10 seconds? Have half a cup of coffee? Brush a short video? In the sealing ring manufacturing industry, 10 seconds is enough to complete the full process of producing 10 hig...

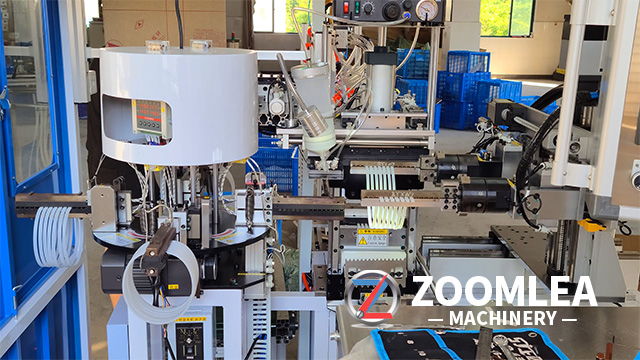

In today’s fiercely competitive manufacturing industry, rising labor costs, difficult efficiency bottlenecks, and poor quality stability have become the “three major mountains” weig...

In this era of “fast fish eating slow fish”, efficiency is the lifeline. Dear business owners and project leaders, please stop working on your reports for a moment. Let’s do a strai...

In precision manufacturing fields such as automotive, aerospace, and electronic equipment, the quality of sealing rings directly determines the reliability and lifespan of products. However, traditio...

In the red ocean of manufacturing, every second counts as cost, and every good product is profit. While you are still struggling with difficulties in recruiting workers, high labor costs, and product...

In the sealing ring manufacturing industry, efficiency and quality have always been the core propositions for enterprise survival and development. Faced with the stringent requirements for sealing ri...

When workshop workers sweat profusely but still cannot meet the order delivery deadline, when labor costs erode profits but they dare not raise prices, and when customers switch to competitors due to...

In the field of industrial manufacturing, small and medium-sized sealing ring production enterprises often fall into the quagmire of price wars – accepting orders at low prices, compressing pro...

In the fiercely competitive business world, business owners, unit leaders, and project leaders rack their brains every day to improve efficiency and reduce costs. Especially in the manufacturing indu...

In the current fiercely competitive manufacturing industry, every penny of a company has to be spent on the cutting edge. Traditional sealing ring production relies on intensive manual labor and disp...

In the fiercely competitive industrial manufacturing field, efficiency and cost have always been the core propositions for the survival and development of enterprises. For the sealing ring production...

In the current fiercely competitive manufacturing industry, balancing production efficiency and cost control has become the key to the survival of enterprises. Traditional sealing ring production rel...

In the precision world of manufacturing, sealing rings are the core components that ensure the safe and stable operation of equipment. From the battery pack of new energy vehicles to the fuel tank of...

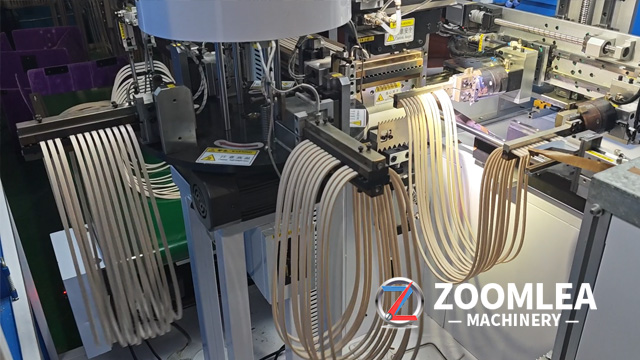

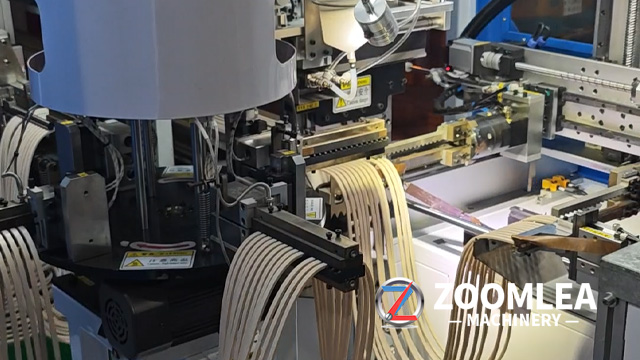

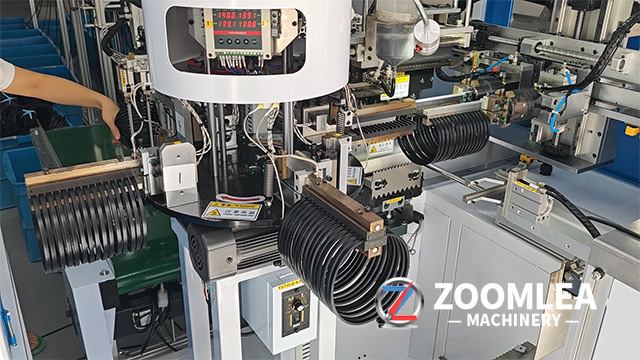

In the wave of transformation and upgrading in the manufacturing industry, the production of sealing rings is undergoing a disruptive change. Traditional production lines rely on tedious processes su...

4000 pieces per hour! This speed is like a money printing machine! “In the workshop of a sealing component factory in Guangdong, production line leader Mr. Li stared at the operation screen of ...

In the fiercely competitive global manufacturing market, a previously unknown factory has achieved a dual leap in production capacity and quality with the Zoomlea Seal ring bonding machine. Its produ...

In the field of industrial manufacturing, sealing rings are the core components that ensure the sealing performance of equipment, and their production efficiency and quality directly determine the ma...

In the sealing ring manufacturing industry, the principle of “efficiency is life” has never been so clear. Under the traditional manual bonding mode, it takes 8 workers to work in three s...