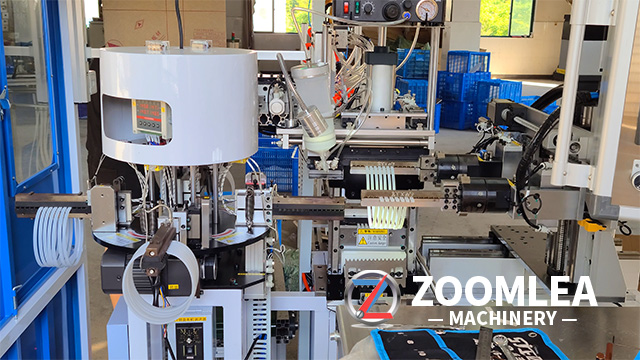

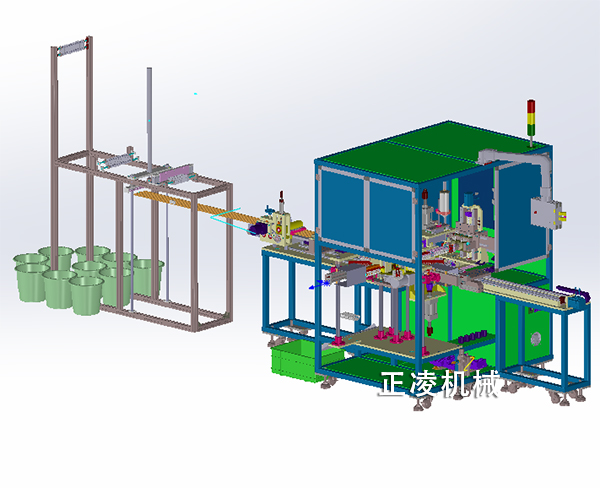

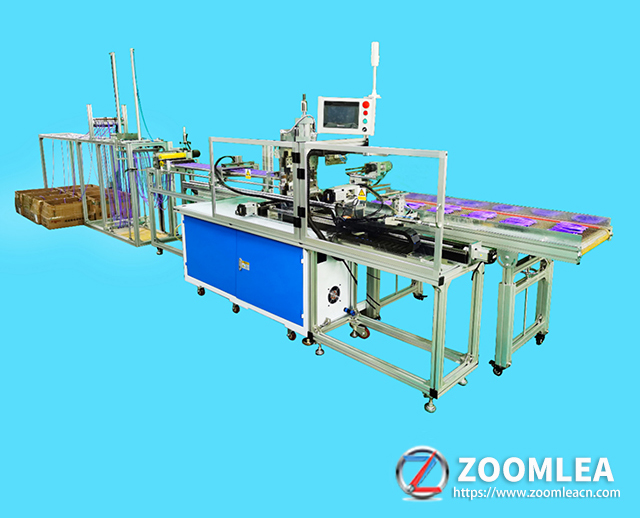

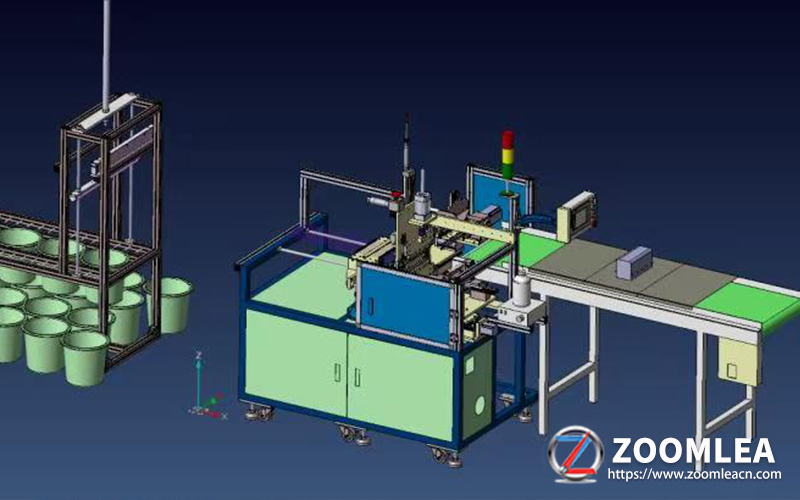

O ring bonding machine

In high-precision fields such as automobile manufacturing, aerospace, electronics, etc., O-rings serve as core sealing components, and their production efficiency and quality directly determine the competitiveness of enterprises. The traditional manual bonding method faces pain points such as low efficiency, high defect rate, and rising labor costs, while the Zoomlea O ring bonding machine has become the preferred solution for intelligent upgrading in the industry with its disruptive performance of “bonding 10 pieces in 10 seconds and daily production of 86000 pieces per machine”.

1、 Core Advantage: Dual Revolution of Efficiency and Quality

Ultra high speed production capacity

10 seconds/10 pieces: The multi station parallel system achieves continuous production, with an hourly output of over 4000 pieces and a daily production capacity of 86000 pieces, which is more than 30 times more efficient than manual labor.

All year round: 24-hour stable operation, supporting fast delivery of large orders and shortening delivery cycles by more than 50%.

Zero defect quality assurance

Precision glue coating technology: using high-precision metering pumps to avoid defects such as bubbles and glue overflow.

Intelligent temperature control system: Low temperature vulcanization process ensures that materials such as silicone and EPDM rubber do not deform, and the bonding strength is improved.

Full material compatibility

Support diverse materials such as silicone, rubber, foam strips, and shaped sealing rings, suitable for high standard requirements such as food grade and aerospace grade.

Modular design supports quick switching of specifications, and both short and long sealing rings can be efficiently produced.

2、 Technological breakthrough: from “human wave tactics” to “unmanned intelligent manufacturing”

Full process automation

Automatic feeding cutting bonding unloading: No need for manual intervention, reducing labor costs by 80% and avoiding human errors.

AI dynamic optimization: By using machine learning algorithms to automatically adjust parameters and adapt to different material characteristics, production efficiency continues to improve.

Minimalist user interface

Touch screen one click start, ordinary workers can get started in 30 minutes.

3、 Industry application: Accurately matching diverse needs

automobile making

Efficient production of door seals, engine hood gaskets, etc., to meet stringent requirements such as high temperature resistance and oil pollution resistance.

Electronic appliances

Provide micron level precision waterproof sealing rings for mobile phones and tablets to enhance product reliability.

EADS

Customized production of aerospace grade silicone sealing rings that are resistant to extreme temperature differences to ensure equipment safety.

Food and Medical

Food grade materials and dust-free workshop design comply with international certification standards such as FDA and ISO.

4、 Service commitment: worry free guarantee throughout the entire process

Free trial run: Provide customized solutions to verify production feasibility.

24-hour response: With nationwide service network coverage, engineers will be on site within 48 hours to provide support.

Zoomlea O ring bonding machine – making every sealing ring a quality benchmark!

Consult now for exclusive solutions and embark on a new chapter in intelligent manufacturing!

📞 Contact phone number:+86-14757880998

English/product/o-ring-bonding-machine.html

English/product/o-ring-bonding-machine.html Afrikaans/product/o-ring-bonding-machine.html?lang=af

Afrikaans/product/o-ring-bonding-machine.html?lang=af አማርኛ/product/o-ring-bonding-machine.html?lang=am

አማርኛ/product/o-ring-bonding-machine.html?lang=am العربية/product/o-ring-bonding-machine.html?lang=ar

العربية/product/o-ring-bonding-machine.html?lang=ar Հայերեն/product/o-ring-bonding-machine.html?lang=hy

Հայերեն/product/o-ring-bonding-machine.html?lang=hy azərbaycan dili/product/o-ring-bonding-machine.html?lang=az

azərbaycan dili/product/o-ring-bonding-machine.html?lang=az Euskara/product/o-ring-bonding-machine.html?lang=eu

Euskara/product/o-ring-bonding-machine.html?lang=eu Беларуская/product/o-ring-bonding-machine.html?lang=be

Беларуская/product/o-ring-bonding-machine.html?lang=be বাংলা/product/o-ring-bonding-machine.html?lang=bn

বাংলা/product/o-ring-bonding-machine.html?lang=bn bosanski jezik/product/o-ring-bonding-machine.html?lang=bs

bosanski jezik/product/o-ring-bonding-machine.html?lang=bs Български/product/o-ring-bonding-machine.html?lang=bg

Български/product/o-ring-bonding-machine.html?lang=bg မြန်မာစာ/product/o-ring-bonding-machine.html?lang=my

မြန်မာစာ/product/o-ring-bonding-machine.html?lang=my Català/product/o-ring-bonding-machine.html?lang=ca

Català/product/o-ring-bonding-machine.html?lang=ca 粤语/product/o-ring-bonding-machine.html?lang=yue

粤语/product/o-ring-bonding-machine.html?lang=yue 中文(简体)/product/o-ring-bonding-machine.html?lang=zh

中文(简体)/product/o-ring-bonding-machine.html?lang=zh 中文(漢字)/product/o-ring-bonding-machine.html?lang=zh-tw

中文(漢字)/product/o-ring-bonding-machine.html?lang=zh-tw Hrvatski/product/o-ring-bonding-machine.html?lang=hr

Hrvatski/product/o-ring-bonding-machine.html?lang=hr Čeština/product/o-ring-bonding-machine.html?lang=cs

Čeština/product/o-ring-bonding-machine.html?lang=cs Dansk/product/o-ring-bonding-machine.html?lang=da

Dansk/product/o-ring-bonding-machine.html?lang=da Nederlands/product/o-ring-bonding-machine.html?lang=nl

Nederlands/product/o-ring-bonding-machine.html?lang=nl Esperanto/product/o-ring-bonding-machine.html?lang=eo

Esperanto/product/o-ring-bonding-machine.html?lang=eo Wikang Filipino/product/o-ring-bonding-machine.html?lang=fil

Wikang Filipino/product/o-ring-bonding-machine.html?lang=fil Suomi/product/o-ring-bonding-machine.html?lang=fi

Suomi/product/o-ring-bonding-machine.html?lang=fi Français/product/o-ring-bonding-machine.html?lang=fr

Français/product/o-ring-bonding-machine.html?lang=fr Frysk/product/o-ring-bonding-machine.html?lang=fy

Frysk/product/o-ring-bonding-machine.html?lang=fy Deutsch/product/o-ring-bonding-machine.html?lang=de

Deutsch/product/o-ring-bonding-machine.html?lang=de Ελληνικά/product/o-ring-bonding-machine.html?lang=el

Ελληνικά/product/o-ring-bonding-machine.html?lang=el Harshen Hausa/product/o-ring-bonding-machine.html?lang=ha

Harshen Hausa/product/o-ring-bonding-machine.html?lang=ha Hmoob Daw/product/o-ring-bonding-machine.html?lang=mw

Hmoob Daw/product/o-ring-bonding-machine.html?lang=mw Мары йӹлмӹ/product/o-ring-bonding-machine.html?lang=mrj

Мары йӹлмӹ/product/o-ring-bonding-machine.html?lang=mrj हिन्दी; हिंदी/product/o-ring-bonding-machine.html?lang=hi

हिन्दी; हिंदी/product/o-ring-bonding-machine.html?lang=hi Magyar/product/o-ring-bonding-machine.html?lang=hu

Magyar/product/o-ring-bonding-machine.html?lang=hu Íslenska/product/o-ring-bonding-machine.html?lang=is

Íslenska/product/o-ring-bonding-machine.html?lang=is Bahasa Indonesia/product/o-ring-bonding-machine.html?lang=id

Bahasa Indonesia/product/o-ring-bonding-machine.html?lang=id Gaeilge/product/o-ring-bonding-machine.html?lang=ga

Gaeilge/product/o-ring-bonding-machine.html?lang=ga Italiano/product/o-ring-bonding-machine.html?lang=it

Italiano/product/o-ring-bonding-machine.html?lang=it 日本語/product/o-ring-bonding-machine.html?lang=ja

日本語/product/o-ring-bonding-machine.html?lang=ja basa Jawa/product/o-ring-bonding-machine.html?lang=jw

basa Jawa/product/o-ring-bonding-machine.html?lang=jw Қазақ тілі/product/o-ring-bonding-machine.html?lang=kk

Қазақ тілі/product/o-ring-bonding-machine.html?lang=kk ភាសាខ្មែរ/product/o-ring-bonding-machine.html?lang=km

ភាសាខ្មែរ/product/o-ring-bonding-machine.html?lang=km кыргыз тили/product/o-ring-bonding-machine.html?lang=ky

кыргыз тили/product/o-ring-bonding-machine.html?lang=ky 한국어/product/o-ring-bonding-machine.html?lang=ko

한국어/product/o-ring-bonding-machine.html?lang=ko ພາສາລາວ/product/o-ring-bonding-machine.html?lang=lo

ພາສາລາວ/product/o-ring-bonding-machine.html?lang=lo Latīna/product/o-ring-bonding-machine.html?lang=la

Latīna/product/o-ring-bonding-machine.html?lang=la македонски јазик/product/o-ring-bonding-machine.html?lang=mk

македонски јазик/product/o-ring-bonding-machine.html?lang=mk Malagasy fiteny/product/o-ring-bonding-machine.html?lang=mg

Malagasy fiteny/product/o-ring-bonding-machine.html?lang=mg Bahasa Melayu/product/o-ring-bonding-machine.html?lang=ms

Bahasa Melayu/product/o-ring-bonding-machine.html?lang=ms മലയാളം/product/o-ring-bonding-machine.html?lang=ml

മലയാളം/product/o-ring-bonding-machine.html?lang=ml Malti/product/o-ring-bonding-machine.html?lang=mt

Malti/product/o-ring-bonding-machine.html?lang=mt मराठी/product/o-ring-bonding-machine.html?lang=mr

मराठी/product/o-ring-bonding-machine.html?lang=mr марий йылме/product/o-ring-bonding-machine.html?lang=mhr

марий йылме/product/o-ring-bonding-machine.html?lang=mhr नेपाली/product/o-ring-bonding-machine.html?lang=ne

नेपाली/product/o-ring-bonding-machine.html?lang=ne Norsk/product/o-ring-bonding-machine.html?lang=no

Norsk/product/o-ring-bonding-machine.html?lang=no پارسی/product/o-ring-bonding-machine.html?lang=fa

پارسی/product/o-ring-bonding-machine.html?lang=fa Polski/product/o-ring-bonding-machine.html?lang=pl

Polski/product/o-ring-bonding-machine.html?lang=pl Português/product/o-ring-bonding-machine.html?lang=pt

Português/product/o-ring-bonding-machine.html?lang=pt ਪੰਜਾਬੀ/product/o-ring-bonding-machine.html?lang=pa

ਪੰਜਾਬੀ/product/o-ring-bonding-machine.html?lang=pa Română/product/o-ring-bonding-machine.html?lang=ro

Română/product/o-ring-bonding-machine.html?lang=ro Русский/product/o-ring-bonding-machine.html?lang=ru

Русский/product/o-ring-bonding-machine.html?lang=ru Sesotho/product/o-ring-bonding-machine.html?lang=st

Sesotho/product/o-ring-bonding-machine.html?lang=st سنڌي/product/o-ring-bonding-machine.html?lang=sd

سنڌي/product/o-ring-bonding-machine.html?lang=sd Slovenčina/product/o-ring-bonding-machine.html?lang=sk

Slovenčina/product/o-ring-bonding-machine.html?lang=sk Slovenščina/product/o-ring-bonding-machine.html?lang=sl

Slovenščina/product/o-ring-bonding-machine.html?lang=sl Español/product/o-ring-bonding-machine.html?lang=es

Español/product/o-ring-bonding-machine.html?lang=es Svenska/product/o-ring-bonding-machine.html?lang=sv

Svenska/product/o-ring-bonding-machine.html?lang=sv Reo Mā`ohi'/product/o-ring-bonding-machine.html?lang=ty

Reo Mā`ohi'/product/o-ring-bonding-machine.html?lang=ty தமிழ்/product/o-ring-bonding-machine.html?lang=ta

தமிழ்/product/o-ring-bonding-machine.html?lang=ta ภาษาไทย/product/o-ring-bonding-machine.html?lang=th

ภาษาไทย/product/o-ring-bonding-machine.html?lang=th faka Tonga/product/o-ring-bonding-machine.html?lang=to

faka Tonga/product/o-ring-bonding-machine.html?lang=to Türkçe/product/o-ring-bonding-machine.html?lang=tr

Türkçe/product/o-ring-bonding-machine.html?lang=tr Українська/product/o-ring-bonding-machine.html?lang=uk

Українська/product/o-ring-bonding-machine.html?lang=uk اردو/product/o-ring-bonding-machine.html?lang=ur

اردو/product/o-ring-bonding-machine.html?lang=ur Oʻzbek tili/product/o-ring-bonding-machine.html?lang=uz

Oʻzbek tili/product/o-ring-bonding-machine.html?lang=uz Tiếng Việt/product/o-ring-bonding-machine.html?lang=vi

Tiếng Việt/product/o-ring-bonding-machine.html?lang=vi isiXhosa/product/o-ring-bonding-machine.html?lang=xh

isiXhosa/product/o-ring-bonding-machine.html?lang=xh èdè Yorùbá/product/o-ring-bonding-machine.html?lang=yo

èdè Yorùbá/product/o-ring-bonding-machine.html?lang=yo

MESSAGE