The practical data of a certain aviation parts enterprise is shocking: tasks that originally required 10 workers and 8 hours to complete can now be completed in 2 hours with only 1 worker operating t...

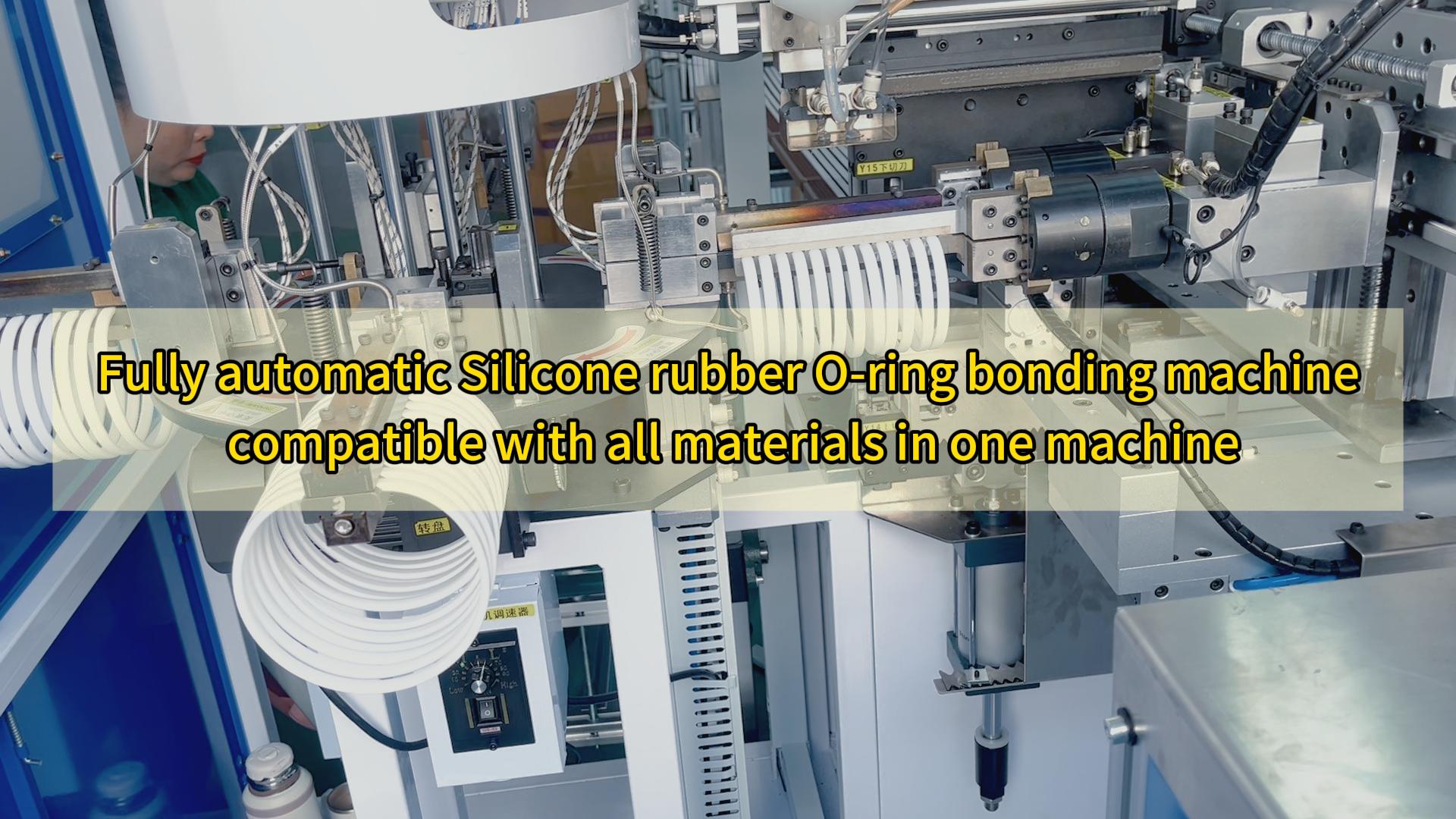

zoomlea seal ring bonding machine takes “one machine compatible with all materials” as its core, paving the way for intelligent upgrading of enterprises; One device can be compatible ...

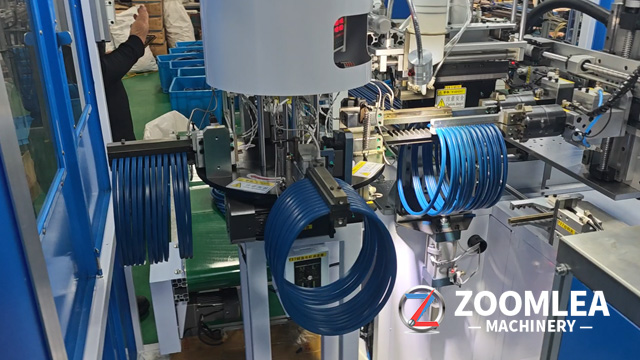

The zoomlea seal ring bonding machine adopts a high-speed servo drive system and multi station synchronous operation design, achieving full process automation from feeding, cutting, bonding to un...

In the sealing ring manufacturing industry, the game between production capacity and efficiency has never stopped. Under the traditional manual bonding mode, workers have limited hand speed and there...

In the field of seal ring manufacturing, material compatibility has always been a key bottleneck that restricts production efficiency and cost. Traditional equipment often can only adapt to a single ...

What can be done in 10 seconds? Have half a cup of coffee? Brush a short video? In the sealing ring manufacturing industry, 10 seconds is enough to complete the full process of producing 10 hig...

The new year is approaching, and the battlefield of competition in the manufacturing industry is filled with smoke. When peers are still struggling with rising labor costs, production capacity bottle...

High labor costs, limited production capacity, and fluctuating yield rates? Let’s give this Zoomlea seal ring bonding machine a try. It has multiple parallel stations, 10 pieces in 10 secon...

As the festive atmosphere intensifies, are you fully prepared for efficient production in the coming year as you immerse yourself in the joy of the holiday and plan your business blueprint for the ne...

In today’s fiercely competitive manufacturing industry, rising labor costs, difficult efficiency bottlenecks, and poor quality stability have become the “three major mountains” weig...

Have you prepared a production line for efficient production in 2026? Don’t wait for production capacity to be blocked before changing equipment! Zoomlea seal ring bonding machine is equipp...

In the fiercely competitive business battlefield, small and medium-sized enterprises are often trapped in the low-end links of the industrial chain, looking at the seemingly unattainable “high ...

In this era where “fast fish eat slow fish”, is your production line still “running slowly by hand”? Bosses, let’s do some math: what’s the most expensive in to...

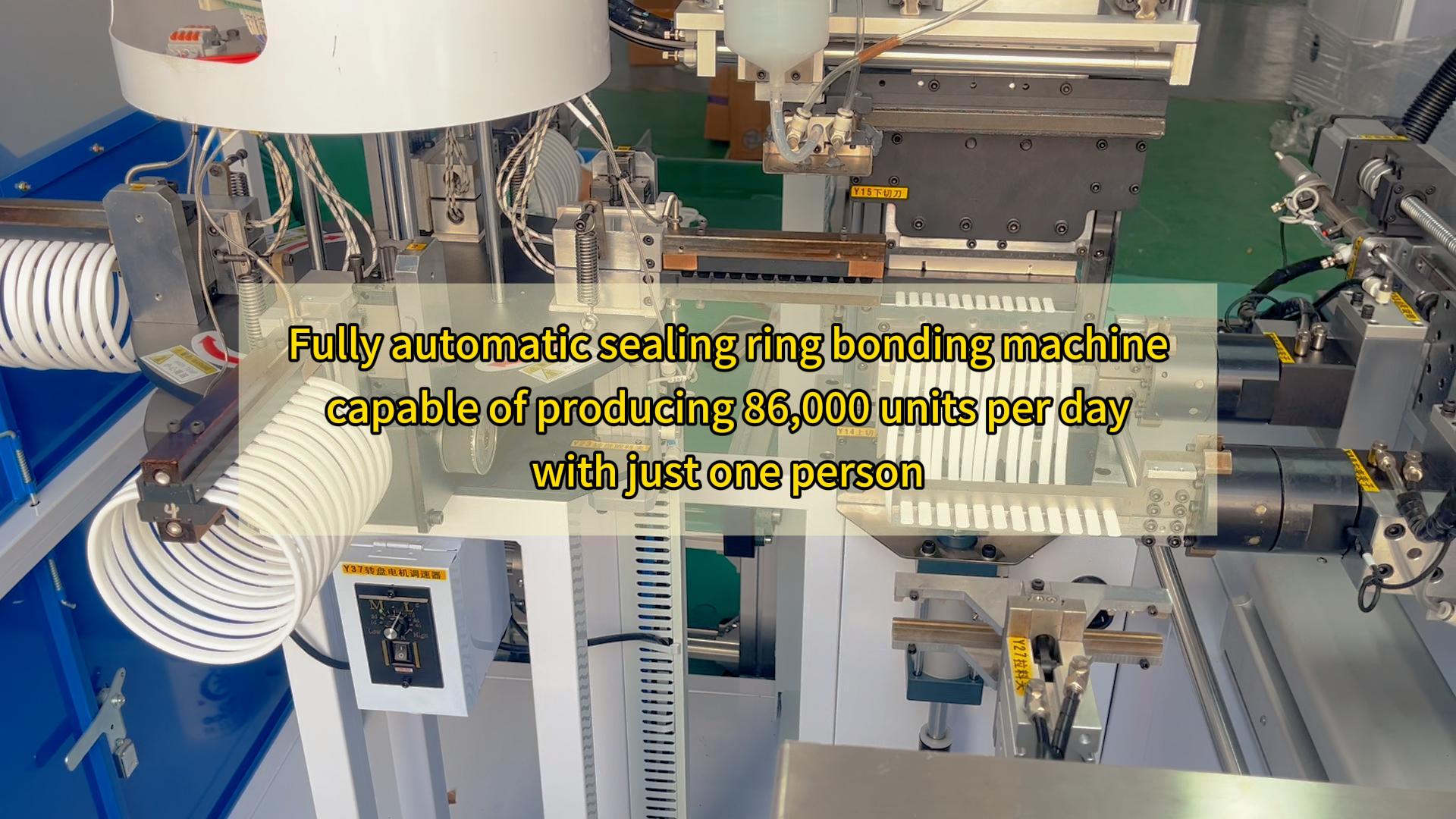

Is your production line still relying on manual labor for slow running? Take a look at this Zoomlea seal ring bonding machine! One person, one machine, with a daily output of 86000! Second level ...

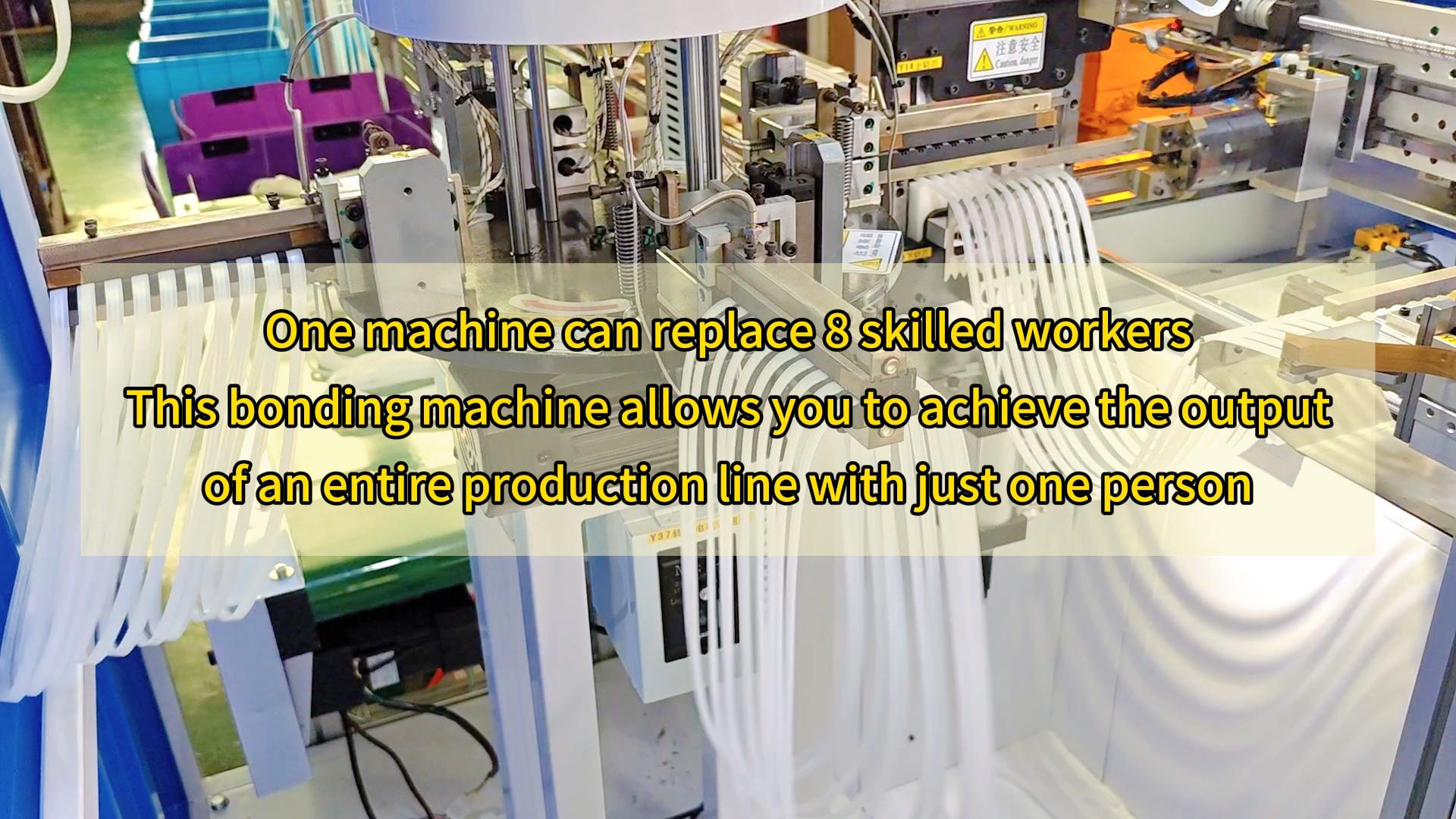

Take a look at this Zoomlea seal ring bonding machine! In just one hour, it can produce 4,000 units! One machine can replace up to 8 skilled workers! Only one person is needed to monitor the mach...

How many people are needed to produce 86,000 sealing rings per day? Zoomlea seal ring bonding machine can achieve a production capacity of 86,000 units with just one person! The equipment adopts ...

In the precision manufacturing industry, bosses are all pursuing a seemingly impossible “impossible triangle”: extremely high production, extremely low labor costs, and extremely stable p...

In this era of “fast fish eating slow fish”, efficiency is the lifeline. Dear business owners and project leaders, please stop working on your reports for a moment. Let’s do a strai...

In precision manufacturing fields such as automotive, aerospace, and electronic equipment, the quality of sealing rings directly determines the reliability and lifespan of products. However, traditio...

In the red ocean of manufacturing, efficiency is life, and cost is king. While you are still struggling with slow manual bonding, high defect rates, and delayed order delivery, a “nuclear explo...